BSPT vs BSPP Threads: Everything You Need to Know

Table of Contents

Introduction

BSPT (British Standard Pipe Tapered) and BSPP (British Standard Parallel Pipe) threads are two distinct types of thread profiles used in various industries, particularly in plumbing and hydraulic systems. Both thread types play a vital role in ensuring the integrity and reliability of fluid and gas transfer systems.

BSPP vs BSPT: What's the Difference?

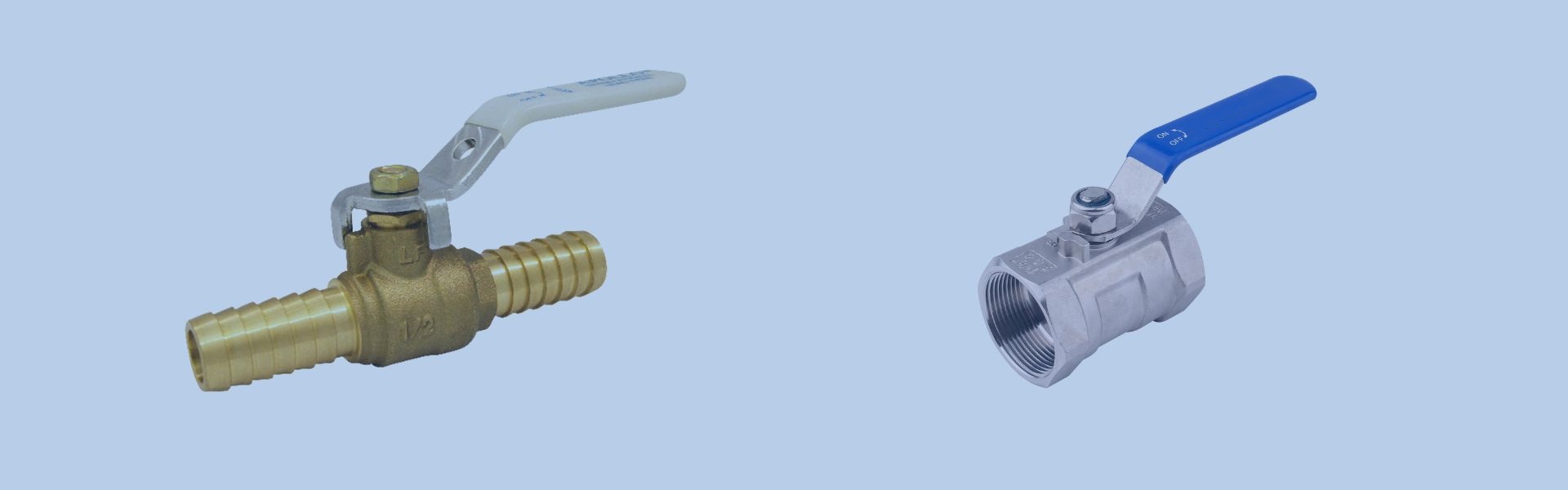

BSPT (British Standard Pipe Tapered) threads are tapered, meaning they get narrower towards the end. This tapering creates a tight seal as the threads wedge together. BSPP (British Standard Parallel Pipe) threads, in contrast, are parallel and require an additional sealing element, such as an O-ring or gasket, to achieve a leak-proof connection. The primary difference between BSPT and BSPP threads lies in their sealing mechanisms and thread profiles: BSPT uses a tapered thread for sealing, while BSPP relies on a parallel thread with a separate seal.

For a deeper understanding of BSPT and BSPP threads, including detailed comparisons, practical applications, and selection tips, continue reading the following sections. This comprehensive guide will provide you with all the information you need to make informed decisions about which thread type to use in your specific applications.

Understanding BSPT Threads

What BSPT Stands For

The R thread (R series) is an abbreviation for British Standard Pipe Taper, also known as BSPT thread. It is one of the thread types standardized under the British Standard Pipe (BSP) system, primarily used for creating pressure-tight joints in pipe systems.

Description of Tapered Threads and Their Sealing Mechanism

BSPT threads are designed with a taper, meaning the diameter of the threads decreases gradually towards the end of the fitting. This tapering is typically at a 1:16 angle (or 55 degrees). The primary sealing mechanism of BSPT threads is through the wedging action of the threads as they are tightened, which creates a metal-to-metal seal. The threads deform slightly under pressure, filling any gaps and ensuring a tight, leak-proof connection without the need for additional sealing materials, although thread sealants like PTFE tape are often used for extra security.

The primary sealing mechanism of BSPT threads is through the wedging action of the threads as they are tightened. When the male and female threads are screwed together, the tapered shape causes the threads to deform slightly under pressure. This deformation helps to fill any gaps between the threads, creating a metal-to-metal seal. The sealing effectiveness increases as the threads are tightened, ensuring a leak-proof connection.

Industries and Systems Where BSPT Threads Are Commonly Used

While the metal-to-metal contact often provides sufficient sealing, additional thread sealants like PTFE (Polytetrafluoroethylene) tape, commonly known as Teflon tape, or pipe dope (thread sealing compound) are frequently used. These sealants add an extra layer of security by filling in any microscopic gaps that might still exist, further preventing leaks. PTFE tape, for instance, is wrapped around the male thread before assembly, providing lubrication during threading and a barrier that enhances the seal.

BSPT threads are known for their robustness and reliability, especially in high-pressure applications. The tapering design not only aids in sealing but also ensures that the connection can withstand significant mechanical stresses and vibrations, making BSPT threads highly dependable for critical applications.

Typical Materials and Manufacturing Standards

BSPT threads are typically manufactured from materials such as stainless steel, brass, and carbon steel. These materials are chosen for their durability, resistance to corrosion, and ability to withstand high pressures. The manufacturing standards for BSPT threads are defined by international standards such as ISO 7-1, BS 21, and DIN 2999, which specify the dimensions, tolerances, and other technical requirements to ensure compatibility and performance across different manufacturers and applications.

Understanding BSPP Threads

What BSPP Stands For

BSPP stands for British Standard Pipe Parallel. BSPP thread female thread abbreviation is Rc thread. It is another thread type standardized under the British Standard Pipe (BSP) system BSPP threads are designed for use in situations where a reliable, non-leak connection is required, and they are especially common in hydraulic and pneumatic systems.

BSPT threads are widely used in various industries due to their reliable sealing capabilities. Common applications include:

Plumbing: Used extensively in water supply and distribution systems where a tight seal is essential to prevent leaks.

Gas Distribution: Employed in gas lines and fittings, ensuring safe and leak-proof connections in both residential and commercial gas installations.

Hydraulics and Pneumatics: Found in hydraulic and pneumatic systems where high-pressure fluids are conveyed, requiring secure and reliable joints.

Industrial Machinery: Utilized in various industrial machines and equipment that operate under high pressure and require robust pipe connections.

BSPT threads’ ability to form pressure-tight seals makes them a preferred choice in these and other applications where safety and efficiency are paramount.

Description of Parallel Threads and Their Sealing Mechanism

BSPP threads are characterized by their parallel design, meaning the diameter of the threads remains constant along the length of the fitting. Unlike tapered threads, parallel threads do not create a seal through the wedging action of the threads themselves. Instead, BSPP threads rely on an additional sealing element, such as an O-ring, washer, or gasket, to create a leak-proof connection. This sealing element is typically placed at the interface where the threads meet, ensuring that the connection remains secure and leak-free even under pressure.

The parallel thread design of BSPP offers several advantages:

Consistent Thread Engagement: Because the thread diameter does not change, BSPP threads provide a consistent fit along the entire length of the thread engagement. This can make assembly easier and more predictable.

Reduced Stress on Threads: The use of an additional sealing element means that the threads themselves are not solely responsible for creating a seal. This can reduce the stress on the threads and potentially extend the lifespan of the fittings.

Versatility: BSPP threads can be used in a wide range of applications, especially where high reliability and repeated assembly and disassembly are required.

Typical Materials and Manufacturing Standards

BSPP threads are commonly manufactured from materials such as stainless steel, brass, and carbon steel, chosen for their durability, resistance to corrosion, and ability to withstand various environmental conditions. These materials ensure that BSPP fittings can perform reliably in a wide range of applications, from industrial machinery to hydraulic systems.

The manufacturing standards for BSPP threads ensure compatibility and performance across different industries and applications. Key standards include:

ISO 228-1: This international standard specifies the dimensions and tolerances for parallel pipe threads where a pressure-tight joint is not made on the threads.

BS 2779: A British Standard that provides specifications for pipe threads for use where the pressure-tight joint is not made on the threads.

These standards ensure that BSPP threads meet the necessary quality and performance criteria, making them suitable for a wide range of applications.

BSPP Threads Are Commonly Used

BSPP threads are widely used in various industries due to their reliable sealing capabilities and ease of assembly. Some common applications include:

Hydraulics: BSPP threads are extensively used in hydraulic systems, where the reliability and strength of the fittings are critical. The use of O-rings or washers ensures leak-proof connections even under high pressure.

Pneumatics: In pneumatic systems, BSPP threads are preferred for their ability to create secure connections without the risk of leaks. Their parallel design and additional sealing elements make them ideal for applications where air pressure needs to be maintained consistently.

Plumbing: BSPP threads are used in plumbing applications where a reliable and reusable connection is needed. The use of washers or gaskets helps ensure that connections can be assembled and disassembled without compromising the seal.

Industrial Equipment: BSPP threads are found in various types of industrial equipment, including machinery and processing systems, where durable and leak-proof connections are essential.

Automotive: In the automotive industry, BSPP threads are used in systems where reliability and ease of maintenance are important, such as in fuel and hydraulic systems.

Understanding GAS Threads

What GAS Stands For

GAS threads refer to a type of thread standard used primarily in Europe, which is derived from the German term “Gewinde für das Gas” meaning “threads for gas.” These threads are standardized under the DIN (Deutsches Institut für Normung) system, particularly DIN 259 and DIN 2999. They are designed for use in gas and water pipe systems, ensuring safe and secure connections in various applications.

Description of GAS Threads and Their Sealing Mechanism

GAS threads can be either parallel (G thread) or tapered (R thread), similar to the BSP thread system. The key characteristics include:

Parallel GAS Threads (G):

These are similar to BSPP (British Standard Pipe Parallel) threads.

The thread diameter remains constant along the length of the fitting.

Sealing is achieved using a gasket, O-ring, or washer placed at the interface where the threads meet.

Commonly used in applications where frequent disassembly and reassembly are required, as the sealing element can be easily replaced.

Tapered GAS Threads (R):

These are similar to BSPT (British Standard Pipe Tapered) threads.

The thread diameter decreases towards the end of the fitting.

Sealing is accomplished through the wedging action of the threads, which creates a metal-to-metal seal.

Often used in high-pressure applications where a secure and leak-proof connection is essential.

The primary difference between the parallel and tapered GAS threads lies in their sealing mechanisms. Parallel threads rely on additional sealing elements, while tapered threads create a seal through the deformation and wedging of the threads.

Typical Materials and Manufacturing Standards

GAS threads are typically manufactured from materials such as brass, stainless steel, and carbon steel, selected for their durability, corrosion resistance, and suitability for various environmental conditions. The manufacturing standards for GAS threads ensure compatibility and performance across different applications. Key standards include:

DIN 259: Specifies the dimensions and tolerances for pipe threads where a pressure-tight joint is not made on the threads.

DIN 2999: Details the requirements for pipe threads with pressure-tight joints, similar to ISO 7-1 for BSP threads.

These standards ensure that GAS threads meet the necessary quality and performance criteria, making them suitable for a wide range of applications.

Practical Considerations for Selection

When selecting between BSPT (British Standard Pipe Tapered) and BSPP (British Standard Pipe Parallel) threads, several factors should be considered to ensure optimal performance and reliability.

Factors to Consider

Pressure Requirements

BSPT: Ideal for high-pressure applications due to its tapered design that provides a robust metal-to-metal seal.

BSPP: Suitable for lower to medium pressure applications where a gasket or O-ring can be used to achieve a seal.

Frequency of Disassembly

BSPT: Less suitable for frequent disassembly due to potential thread damage when re-tightened.

BSPP: Better for applications requiring regular maintenance, as replaceable components like gaskets or O-rings provide the seal.

Application-Specific Recommendations

Hydraulic Systems: BSPP threads are often preferred due to their ability to maintain a reliable seal with an O-ring, making them suitable for systems requiring frequent maintenance.

Gas Lines: BSPT threads are recommended for gas lines due to their ability to create a pressure-tight seal without additional components.

Water Supply: Both BSPT and BSPP can be used, but BSPT is typically chosen for higher-pressure water systems, while BSPP is used for systems requiring ease of maintenance.

Industrial Machinery: Choose BSPT for high-pressure fluid transfer and BSPP for systems with routine maintenance needs.

Conclusion

In summary, BSPT and BSPP threads are distinct in their design and sealing mechanisms. BSPT threads taper to create a metal-to-metal seal ideal for high-pressure applications, while BSPP threads remain parallel, relying on gaskets or O-rings for sealing, making them suitable for systems requiring frequent maintenance. Choosing the correct thread type is crucial for ensuring system integrity, reliability, and safety. By understanding the specific needs of your application and the characteristics of each thread type, you can make informed decisions that enhance the performance and longevity of your installations.

FAQ

What is the difference between BSPP and BSPT threads?

BSPP (British Standard Pipe Parallel) threads have a constant diameter along their length and are sealed using a washer or O-ring. BSPT (British Standard Pipe Tapered) threads, on the other hand, taper along their length, creating a seal through the threads themselves as they tighten.

Which one is better for hydraulic applications, BSPP or BSPT?

Both BSPP and BSPT threads are commonly used in hydraulic applications, but BSPP threads are generally preferred due to their parallel design, which allows for a reliable seal with a washer or O-ring, reducing the risk of leaks.

Can BSPP and BSPT threads be used together?

BSPP and BSPT threads should not be used together because they have different sealing methods and thread profiles. Combining them can result in poor sealing and potential leaks.

How can I identify BSPP and BSPT threads?

BSPP threads are parallel and maintain the same diameter throughout their length. BSPT threads are tapered, meaning the diameter decreases along the thread. You can measure the diameter at different points along the thread to identify them.

What are the common applications for BSPP and BSPT threads?

BSPP threads are commonly used in applications where a reliable, leak-proof connection is needed with a washer or O-ring, such as in hydraulic systems and fluid transfer. BSPT threads are often used in piping systems where a tight seal is achieved by the taper of the threads.

Are BSPP and BSPT threads interchangeable with other thread standards?

BSPP and BSPT threads are not interchangeable with other thread standards like NPT (National Pipe Thread) because they have different thread profiles and sealing methods. Using them interchangeably can lead to improper sealing and potential system failure.